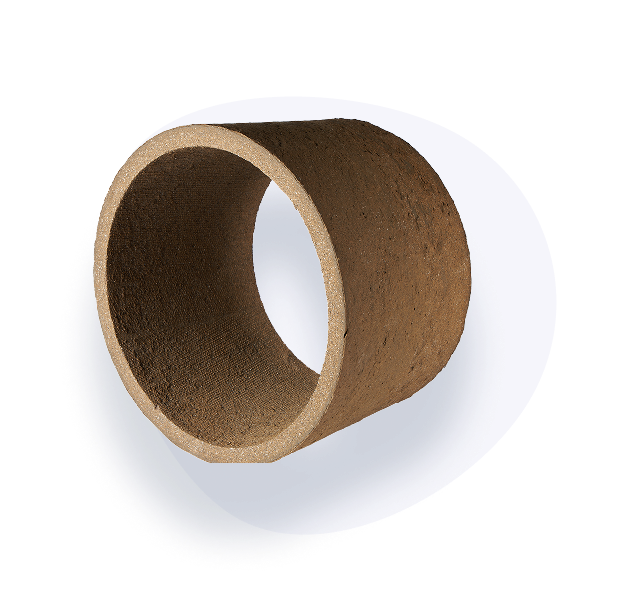

Insulating Neck Down Sleeves a smart solution for directional solidification with minimal metal use and clean riser break-off, especially in iron castings.

Key Features:

- Necked Base Geometry

- Constricted neck controls feeding direction and volume.

- Promotes directional solidification by feeding only the hot spot

- Simplifies post-casting operations — clean knock-off at the neck.

- Insulating (Non-Exothermic) Composition:

- Retains heat using low-conductivity materials.

- No chemical reaction → zero fumes or reaction by-products.

- Keeps the feeder metal molten long enough for effective feeding, especially in iron castings with medium cooling rates.