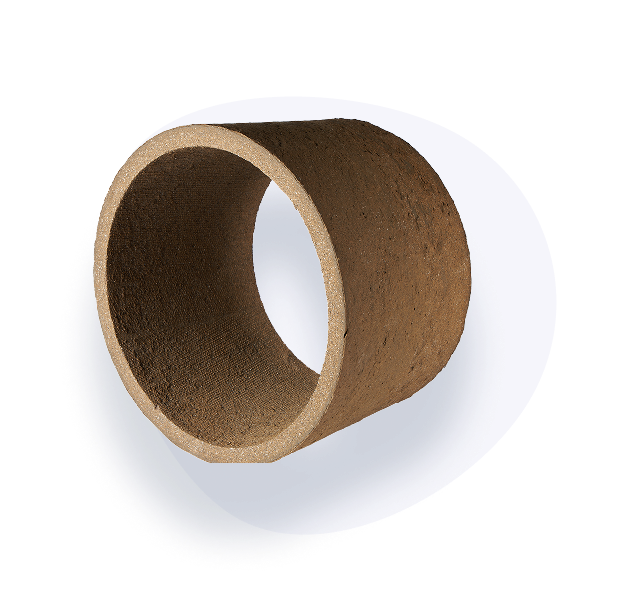

Insulating Open Sleeves ideal for clean, efficient feeding in iron castings where heat retention (not generation) is needed

Key Features:

- Open-Top Configuration

- Molten metal enters from the top during pouring.

- Simple mold setup — often used in vertical or flask riser applications.

- Helps improve casting integrity without compromising mold layout.

- Insulating Material (Non-Exothermic):

- Composed of low thermal conductivity refractory materials

- Retains heat in the riser metal without any combustion or fume generation.

- Filter inserts for slag control

- Optional Add-ons:

- Hot-topping covers/lids

- Collars or height extenders

- Filter inserts for slag control